The following are the general steps and key points for assembling bicycle related connecting pieces. Different types of connecting pieces may have some differences, and specific operations need to be adjusted according to the actual situation:

preparation

Confirm parts: Identify the connecting pieces and related accessories that need to be assembled, and check for any missing or damaged components. For example, if it is a connecting plate for a bicycle brake system, it is necessary to confirm whether the brake wires, brake clamps, connecting plates, and various screws, nuts, and other parts are complete and intact.

Cleaning parts: Use a clean cloth to wipe the surface of the connecting piece and the components that match it, removing oil, dust, and impurities to ensure a tight and smooth connection after assembly.

assembly process

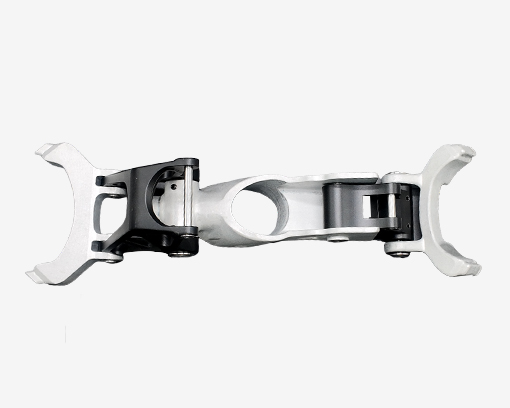

Positioning and installation: Place the connecting piece accurately in the predetermined position. For example, for the seat tube connecting piece of a bicycle, it should be fitted onto the seat tube and the holes on the connecting piece should be aligned with the corresponding installation holes on the seat tube and frame; For the connecting plate of the transmission system, it is necessary to accurately install the connecting plate in the appropriate position according to the direction of the transmission line and the installation position of the transmission, to ensure that the connecting plate can correctly transmit force and achieve the transmission function.

Inserting connectors: Insert relevant connectors such as screws, pins, etc. into the holes of the connecting piece and corresponding components. During the insertion process, ensure that the connector is inserted vertically to avoid tilting and causing unstable installation or damage to the threads. If installing a connecting piece with a spring, pay attention to the installation position and direction of the spring to ensure that it can exert its elastic function normally. For example, the spring in the brake connector should be installed in a position that allows the brake clamp to quickly reset when released.

Tighten and fix: Use appropriate tools such as wrenches, screwdrivers, etc. to tighten the screws or nuts to secure the connecting piece to the relevant components. When tightening, pay attention to even force to avoid deformation or damage to the connecting piece or component due to excessive force, and do not loosen too much to prevent the connecting piece from loosening during use. For connections that require specific torque values, a torque wrench should be used to ensure installation quality meets requirements. For example, there are strict regulations on the tightening torque of screws on certain key parts of the bicycle frame's connecting plates to ensure the strength and stability of the frame.

Inspection and debugging

Appearance inspection: After assembly, carefully check whether the installation of the connecting piece is flat, whether there are any twisted, deformed or protruding parts, to avoid scratching the rider or interfering with other components during use.

Functional testing: Conduct functional testing on the systems involved in the connection piece. For example, for brake pads, it is necessary to check the braking effect of the brake system to ensure that the brake clamp can clamp the brake disc or brake block properly and effectively grip the wheel edge, and that the brake clamp can quickly reset after releasing the brake lever; For the variable speed connecting plate, it is necessary to test whether the transmission can accurately switch between different gears, whether the shifting is smooth, and whether there is any gear jumping or jamming phenomenon.

Fine tuning and calibration: Based on the results of functional testing, make necessary adjustments and calibrations to the connecting piece. If uneven braking force is found, it may be necessary to adjust the position of the brake connecting pad or the tension of the brake wire; If the transmission is not accurate, it may be necessary to readjust the connection angle or length between the transmission connecting plate and the gearbox to achieve the best working condition of the entire system.